01/HY Series Composite polyether >>

01/HY Series Composite polyether >>

HY series polyurethane hard foam combination polyether is widely used in refrigerators, freezers, plates, garage doors, containers, cold storage site spraying, beer cans, water heaters, building insulation and other fields, as insulation materials.

According to hydroxyl value and viscosity, the products are divided into cyclopentane LBA type combination polyether, cyclopentane 245FA type combination polyether, cyclopentane type combination polyether, Appearance: brown-yellow viscous liquid, no solid impurities.

The manual foaming conditions of refrigerators and freezers are shown in the table

Project | unit | Testing standard |

Material a (combined polyether), material B (MDI) | ℃ | 20±2 |

Material a (combined polyether): material B (MDI) | 1:1.20~1.25 | |

Mold temperature | ℃ | 45±5 |

Laboratory temperature | ℃ | 20~25 |

Agitator speed | r/min | 2500±500 |

Cream time | S | 7-10 |

| Fiber time | S | 70±10 |

| Non stick time | S | 100±20 |

| Free bubble density | Kg/m3 | 25±1 |

Table of foaming conditions for high pressure foaming machine in refrigerator and freezer

Project | unit | Testing standard |

Material a (combined polyether), material B (MDI) | ℃ | 20±2 |

Material a (combined polyether): material B (MDI) | 1:1.20~1.25 | |

Material A (combined polyether) pressure | Bar | 110-150 |

B material (MDI) pressure | Bar | 110-150 |

Material A (combined polyether), material B (MDI) pressure difference | Bar | ≤10 |

Mold temperature | ℃ | 45±5 |

cream time | S | 8±2 |

Fiber time | S | 55±5 |

Non stick time | S | 100±20 |

Free bubble density of gun sample | Kg/m³ | 24±1 |

Quality index and application of cyclopentane LBA type composite polyether

Model / index | Hydroxyl value | viscosity | mixture ratio | Reaction characteristics | purpose | |||

cream time S | Fiber time S | Non stick time S | Free Rise Density | |||||

HY-16HL | 350±50 | 500±150 | 1/1.2~1.25 | 10±3 | 60±20 | 65±25 | ≥23 | Refrigerator, freezer |

HY-18HL | 350±50 | 500±150 | 1/1.2~1.25 | 13±3 | 80±20 | 100±25 | ≥23 | Refrigerator, freezer |

Quality index and application of cyclopentane 245fa type composite polyether

Model / index | Hydroxyl value | viscosity | mixture ratio | Reaction characteristics | purpose | |||

cream time S | Fiber time S | Non stick time S | Free Rise Density | |||||

HY-16H2 | 350±50 | 500±150 | 1/1.2~1.25 | 10±3 | 60±20 | 65±25 | ≥23 | Refrigerator, freezer |

HY-18H2 | 350±50 | 500±150 | 1/1.2~1.25 | 13±3 | 80±20 | 100±25 | ≥23 | Refrigerator, freezer |

Quality index and application of cyclopentane polyether

Model / index | Hydroxyl value | viscosity | mixture ratio | Reaction characteristics | purpose | |||

cream time S | Fiber time S | Non stick time S | Free Rise Density | |||||

HY-08H | 330±50 | 400±150 | 1/1.2~1.25 | 4±2 | --- | 12±7 | ≥26 | On site spraying |

HY-09H | 330±50 | 400±150 | 1/1.2~1.25 | 10±5 | 45±10 | 60±20 | ≥27 | Pipes, beer cans, continuous plates |

HY-16H | 330±50 | 400±150 | 1/1.2~1.25 | 10±3 | 60±20 | 65±25 | ≥23 | Refrigerator, freezer |

HY-18H | 330±50 | 400±150 | 1/1.2~1.25 | 15±3 | 80±20 | 100±25 | ≥23 | Refrigerator, freezer |

HY-19H | 330±50 | 400±150 | 1/1.2~1.25 | 10±3 | 60±20 | 65±25 | ≥30 | solar heater |

HY-26H | 330±50 | 400±150 | 1/1.2~1.25 | 20±3 | 90±20 | 120±25 | ≥25 | Garage door |

HY-28H | 330±50 | 400±150 | 1/1.2~1.25 | 25±3 | 110±30 | 130±25 | ≥25 | Common plate |

HY-38H | 330±50 | 400±150 | 1/1.2~1.25 | 30±3 | 130±40 | 180±30 | ≥25 | Large plate and container |

HY-39H | 330±50 | 400±150 | 1/1.2~1.25 | 20±5 | --- | 80±20 | ≥62 | high-density |

Quality index and application of dry composite polyether

Model / index | Hydroxyl value | viscosity | mixture ratio | Reaction characteristics | purpose | |||

cream time S | Fiber time S | Non stick time S | Free Rise Density | |||||

HY-08 | 400±50 | 3500±1000 | 1/1.2~1.25 | 4±2 | --- | 12±7 | ≥26 | On site spraying |

HY-09 | 370±50 | 3500±1000 | 1/1.2~1.25 | 10±5 | 45±10 | 60±20 | ≥27 | Pipes, beer cans, continuous plates |

330±50 | 3500±1000 | |||||||

HY-16 | 400±50 | 3500±1000 | 1/1.2~1.25 | 10±3 | 60±20 | 65±25 | ≥23 | Refrigerator, freezer |

HY-18 | 400±50 | 3500±1000 | 1/1.2~1.25 | 15±3 | 80±20 | 100±25 | ≥23 | Refrigerator, freezer |

HY-19 | 400±50 | 3500±1000 | 1/1.2~1.25 | 10±3 | 60±20 | 65±25 | ≥30 | solar heater |

HY-26 | 400±50 | 3500±1000 | 1/1.2~1.25 | 20±3 | 90±20 | 120±25 | ≥25 | Garage door |

HY-28 | 400±50 | 3500±1000 | 1/1.2~1.25 | 25±3 | 110±30 | 130±25 | ≥25 | Common plate |

HY-38 | 400±50 | 3500±1000 | 1/1.2~1.25 | 30±3 | 130±40 | 180±30 | ≥25 | Large plate and container |

HY-39 | 400±50 | 3500±1000 | 1/1.2~1.25 | 20±5 | --- | 70±20 | ≥62 | high-density |

Technical performance of products

category | project | Technical performance | |

Molded foam | density Kg/m3 | ≥35 | |

compressive strength kpa | ≥110 | ||

Water absorption V/V% | ≤4 | ||

Closed cell rate % | ≥90 | ||

dimensional stability | (-30℃ 24h)% | ≤1 | |

(70℃ 24h)% | ≤1.5 | ||

Product performance>>>

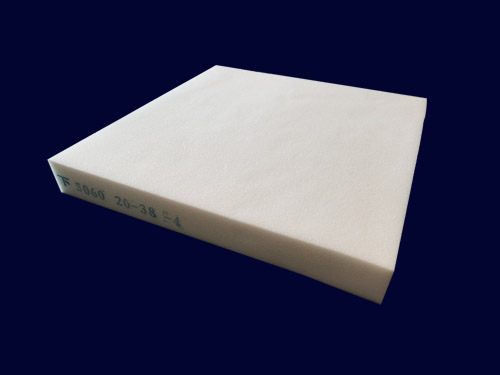

HY series combined polyether is a brownish yellow viscous liquid, and polymethylene polyphenyl polyisocyanate reaction in a certain proportion can produce white or light yellow polyurethane foam body, this foam body has a good thermal insulation and bonding effect.

Packaging and storage>>>

HY series combination polyether adopts iron drum, plastic ton drum sealed packaging, the product should be stored in the indoor explosion-proof, alarm, anti-static, fireproof flowers, cool, dry, ventilated site, avoid direct sunlight and rain, storage temperature of 10℃-25℃ is appropriate, shelf life for six months. During transportation, it is necessary to prevent rain, sun and collision.

Customer case >>>